Introducing the SuperFlow 1020i; an OEM quality flowbench designed specifically for high-volume, end-of-line use. This system provides rapid flow stabilization, quick set point changes and robust durability due to its rugged industrial blower and VFD control. Constructed with a steel / stainless-steel frame and industrial grade components, the SF-1020i eliminates the need for regular maintenance and provides rapid return on investment. The Modbus interface allows easy connection to your OEM controls for automated testing and data collection. With efficiency and longevity in mind, facilities around the world can reduce long-term equipment costs and increase operational efficiency with the innovative SF-1020i from the engineers at SuperFlow.

For several decades, the SuperFlow 1020 Flowbench has been the accepted standard for engine component development especially in the racing/performance market. With the ability to provide positive or negative airflow these benches are great for testing cylinder heads, intake manifolds, carburetors/throttle bodies, exhaust manifolds, and air filters. Over time these benches found their way into the catalyst development and production market.

While the original 1020 proved to be a great tool, the demanding requirements of an end of line test bench stretched the capabilities of the original 1020. The features that made it perfect for the performance market (wooden and laminate cabinet, numerous blower motors, mechanical systems for setting adjustments and the ability to run on single phase electrical power) proved to be problematic for continuous testers. Overheating, slower response time and costly blower motor replacements became part of the accepted norm, causing down time and regular operational expense.

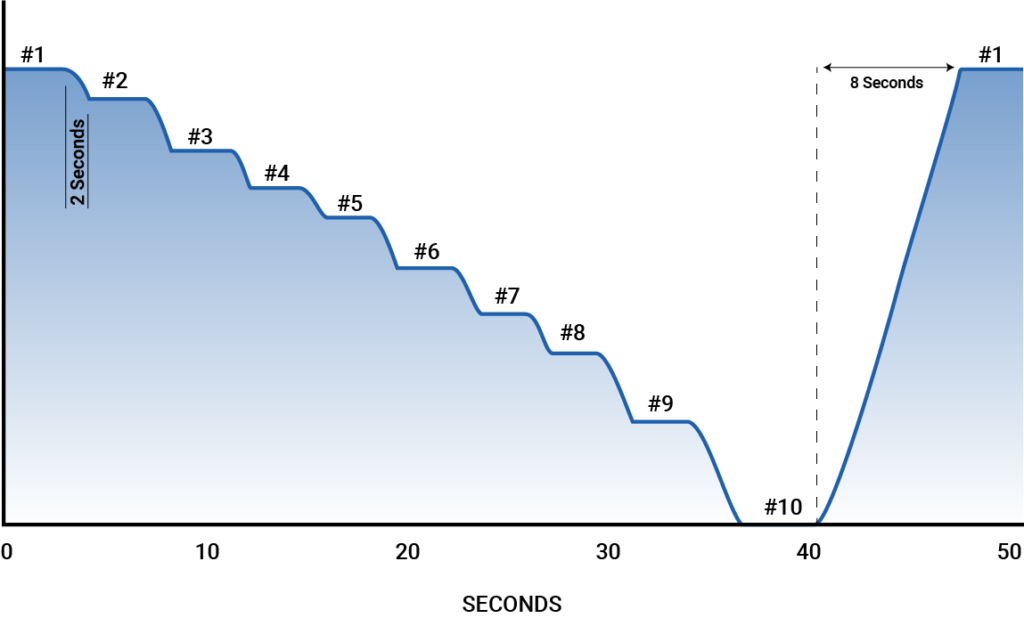

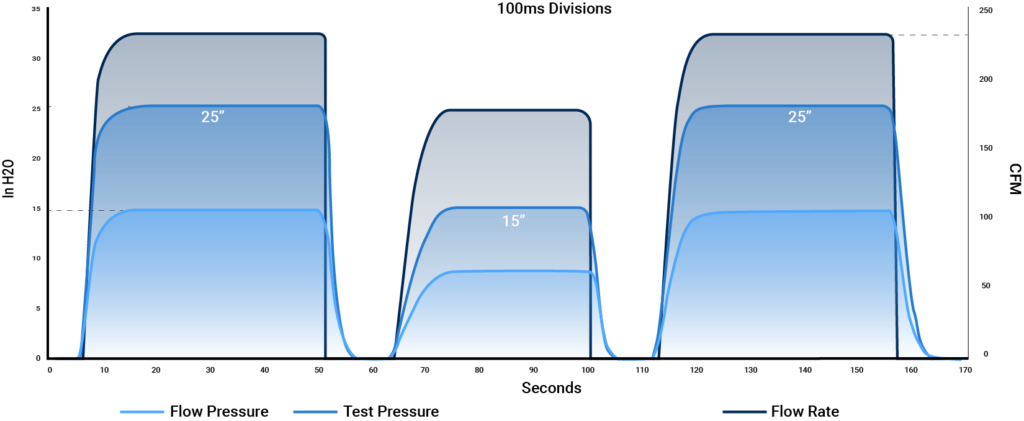

The mechanical actuation speed of the orifice on the 1020i has been increased by a multiple of approximately 7, allowing components can be swapped out in as little as 8 seconds. This accounts for significant efficiency improvements when accounting for hundreds of units tested every day. Data Acquisition and Control Systems Compatibility Data acquisition & control system on the 1020i is now an Industrial PLC. This allows for OEM’s to easily utilize existing embedded software for flowbench testing. Additionally, SuperFlow engineers can customize software and data acquisition patterns for OEM’s specific testing needs.

| Orifice Number | Orifice Diameter | Orifice Area | Flow CFM @ | Flow CFM at Test Pressure | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 1020PB Average | 1020i Average | ||||

| 1 | 0.251 | 0.0495 | 4.44 | ||||||||||||

| 2 | 0.313 | 0.0769 | 6.83 | ||||||||||||

| 3 | 0.375 | 0.1104 | 9.7 | 9.7 | 9.6 | 9.7 | 9.6 | |||||||||

| 4 | 0.563 | 0.2489 | 21.6 | 21.6 | 21.2 | 21.6 | 21.2 | |||||||||

| 5 | 0.754 | 0.4465 | 38.3 | 38.1 | 37.8 | 38.1 | 38.1 | |||||||||

| 6 | 0.815 | 0.522 | 44.6 | 44.7 | 44.7 | 44.7 | 44.7 | |||||||||

| 7 | 1.002 | 0.789 | 67.1 | 66.7 | 66.0 | 66.7 | 66 | |||||||||

| 8 | 1.189 | 1.11 | 94.1 | 94.3 | 96.3 | 93.6 | 93.1 | 93.9 | 94.7 | ||||||||

| 9 | 1.502 | 1.772 | 149.5 | 149.8 | 151.3 | 149.0 | 149.5 | 149.4 | 150.4 | ||||||||

| 10 | 1.688 | 2.238 | 188.3 | 188.5 | 189.9 | 188.5 | 189.9 | |||||||||

| 11 | 1.877 | 2.767 | 232.2 | 231.0 | 230.1 | 231 | 230.1 | |||||||||

| 12 | 2.091 | 3.434 | 287.4 | 287.9 | 289.5 | 288.4 | 287.0 | 289.7 | 287.0 | 288.7 | 287.8 | |||||||

| 13 | 2.376 | 4.434 | 370.1 | 369.7 | 371.0 | 369.2 | 371.0 | 369.4 | 371 | ||||||||

| 14 | 2.875 | 6.492 | 540.5 | 540.5 | 538.9 | 540.5 | 538.9 | |||||||||

| 15 | 3.125 | 7.67 | 637.5 | 637.5 | 640.0 | 637.8 | 636.8 | 637.6 | 638.4 | ||||||||

| 16 | 3.798 | 9.61 | 797.4 | 797.3 | 800.1 | 797.3 | 800.1 | |||||||||

| Specifications | |

|---|---|

| Calibration Test Pressure | 25” of water |

| Range | 0-1,000 cfm |

| Intake Capacity | 1000 cfm ± 5% @ 25” test pressure |

| Power | 480 volt 3-phase, 60 Hz, 30 amps 380 volt 3-phase, 50 Hz, 36 amps |

| Weight | 1,350 lbs (612 kg) |

| Dimensions | 50 x 44” H x 34 in. (122 x 84 x 110 cm) |

| Shipping Weight | 1,685 lbs (764 kg) |

| Shipping Dimensions | 50 x 55” H x 79 in. Crated | (122 x 84 x 110 cm) |

| Orifice Change Rate | 1.5 seconds |

| Stabilization Rate | 7-13 seconds |

Want to here directly from one of our sales reps? Fill out the form and SuperFlow will get back to you with specific solutions for your testing needs.

For new equipment sales, technical service support and parts inquiries please complete this Contact Us form.