The SF-Black Widow EX2 is the highest-capacity extreme performance engine dynamometer on the market. Engineered for unmatched versatility, it can be utilized in both dual-absorber and single-absorber setups to accommodate everything from small-block performance engines to Pro Mod engines to large tractor engines.

Unrivaled in its balance of low-speed torque capacity and high-speed power capability, the SF-Black Widow EX2 features special-grade stainless steel absorbers that resist cavitation for exceptional durability and long service life. Automated test sequences streamline operation with intuitive, step-by-step prompts, ensuring consistent, repeatable results every time.

With an absorber speed range up to 12,000 RPM, this versatile water brake dynamometer delivers up to 6,000 hp (4,470 kW) and 5,000 lb-ft (6,780 Nm) of torque. Backed by SuperFlow’s engineering excellence, the SF-Black Widow EX2 delivers the precision, consistency, and control that define the next generation of extreme performance testing.

The SF-Black Widow EX2 is built with integrated starters, eliminating the need for a bell housing or engine-mounted starter. Precise control of the water equates to precise closed-loop load and speed control of the engine. SuperFlow designed an exclusive quad water valve strategy for the SF-Black Widow EX2. Each of the four servo valves is designed with two valves per absorber, allowing the water brakes to respond quickly to abrupt load changes—such as a nitrous oxide “hit” or a steep rise in engine volumetric efficiency (VE) from a turbo or supercharger—while increasing overall system torque absorption. Independent valves also allow the dyno to operate as a single or dual absorber setup, and one absorber can be easily disconnected to control large engines with rapid, precise adjustments. Stainless steel absorber inlet and outlet valves with high-speed stepper motors control the water flow in and out of the Black Widow’s absorber manifolds, ensuring unmatched responsiveness and performance.

Drive Shaft

High-speed dynamometer drive shaft assembly featuring constant velocity (CV) joints and a driveshaft safety guard.

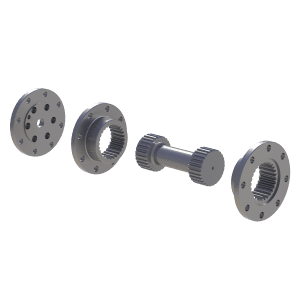

Spline Coupling

Straight-shaft splined engine coupling to the SF Black Widow EX2 dynamometer system. Designed for extreme horsepower, high-speed applications.

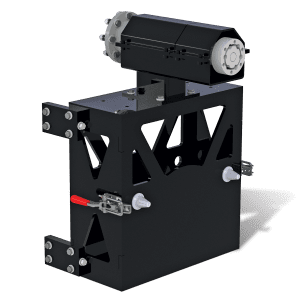

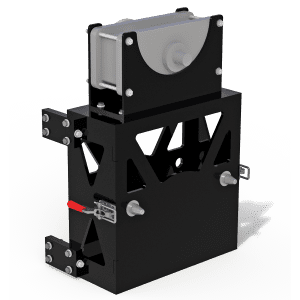

Gear Box

Boosts torque handling at low RPMs with a high-strength speed-increasing gearbox. Perfect for Pro Stock diesel and pulling tractor engine testing.

| Power and Torque | |

|---|---|

| Absorber Type | Water brake, bi-directional |

| Maximum Speed | 12,000 rpm Intermittent |

| Horsepower Capacity | 6,000+ hp (4,470 kW) |

| Torque Capacity | 5,000+ lb-ft (6,780 Nm) |

| Stand Sensor Compliment Includes | |

|---|---|

| Temperature | (1) One: (16) Sixteen-channel thermocouple panel |

| (12) Twelve: Closed tip thermocouples, .125 in (.3175 cm) diameter x 4 in (101 mm) long probe with 5 ft. (152 cm) lead, 0° to 2,000°F (-17.8° – 1,093°C) | |

| (12) Twelve: Swagelock fittings | |

| (13) Twelve: 10 ft (3.048 m) extension cable | |

| Pressure | (1) One: (10) Ten-Channel pressure panel |

| (3) Three: Transducers included standard (-15 to 150 psi, 1-10 bar) | |

| Air / Fuel | (2) Two: Pre-configured analog inputs (Lambda/AFR) |

Overview

The SF-Black Widow EX2 water circuit is a high-performance water system designed to support black widow absorbers applications. This system utilizes dual supply and dual sump pumps to ensure continuous water flow, with variable frequency drives (VFDs) for precision control.

System Components

| Supply Pumps | ||

|---|---|---|

| Quantity | (2) Two (Parallel Operation) | |

| Flow Rate | 300 gpm (1,136 lpm) each | |

| Pressure Requirement | Variable 35-50 psi (2.4 – 3.44 bar) | |

| Motor Rating | 15 hp (11.2 kW) 460V/230V 60Hz 3-Phase) | |

| Pump Type | End-suction centrifugal pump (or equivalent, rated for continuous-duty service) 3 in. Flanged Connections | |

| Drive Control | Each supply pump is equipped with a Variable Frequency Drive (VFD) for: | Precise flow and pressure control |

| Energy efficiency | ||

| Soft start/stop to reduce mechanical wear | ||

| Sump Pumps | ||

|---|---|---|

| Quantity | (2) Two | |

| Flow Rate | 350 gpm (1,325 lpm) each | |

| Motor Rating | 7.5 hp (5.6 kW) (460V/230V 60Hz 3-Phase) | |

| Pump Type | Submersible or vertical sump pump (as application dictates) 3 in. NPTF | |

| Control | Basic float switch operation with optional VFDs for throttling and efficiency | |

| Sump Tank | ||

|---|---|---|

| Minimum Capacity | 150 gal (568 l) | |

| Minimum Height | 36 inches (91.44 cm) | |

| Material | Corrosion-resistant (e.g., polyethylene, fiberglass, or stainless steel depending on fluid compatibility) | |

System Design Considerations

| Piping & Plumbing | |

|---|---|

| Material | PVC, CPVC, stainless steel, or other pressure-rated materials suitable for system fluid |

| Pressure Rating | All plumbing must be rated for at least 60 psi (4 bar) to accommodate pump output and surge |

| Pipe Sizing | Sized for 300 gpm (1,136 lpm) flow with velocity kept within 5-10 fps (1.5-3 mps) to minimize pressure drop |

| Properly supported and anchored to reduce vibration | |

| Pipe runs should be kept as short and as straight as possible | |

| Valves | Isolation valves on all pumps for maintenance |

| Check valves to prevent backflow | |

| Pressure relief valves where necessary | |

| Electrical & Controls | |

|---|---|

| Power RequirementsPressure | (2) Two – 15 hp (11.3kW) supply pumps 460V 20amp per motor (two 30amp breakers) OR 230V 40amp per motor (two 50amp breakers) |

| (2) Two – 7.5 hp (5.6kW) sump pumps 460V 10amp per motor (two 15amp breakers) OR 230V 20amp per motor (two 30amp breakers) | |

| Control Panel | Integrated motor starters or VFDs |

| HMI or local interface for manual control and status display | |

| Alarm indications for pump fault, high/low level, and overpressure | |

Want to here directly from one of our sales reps? Fill out the form and SuperFlow will get back to you with specific solutions for your testing needs.

For new equipment sales, technical service support and parts inquiries please complete this Contact Us form.