Proper Airflow Critical for Test Cell Design

September 21, 2023

Correct Room Ventilation Makes All the Difference!

Ventilation is one of the most overlooked aspects of engine test cell room design. Proper airflow through the test cell is by far one of the most influential factors when assessing the power of your engine.

Fundamentally air is one of the most critical properties of the combustion process. Without air it’s really hard to make any power. Then why would you starve your engine of the one thing it needs most? Easy, it can be a lot of work to get your test cell to flow air correctly, let alone enough CFM. Realistically, most HVAC guys do not understand how much air is needed through a cell. Typical guide lines are 10-15 times the cubic feet of your room in cubic feet of airflow per minute, those requirements could be higher depending on your power level. A heat balance should be done to ensure you have enough airflow.

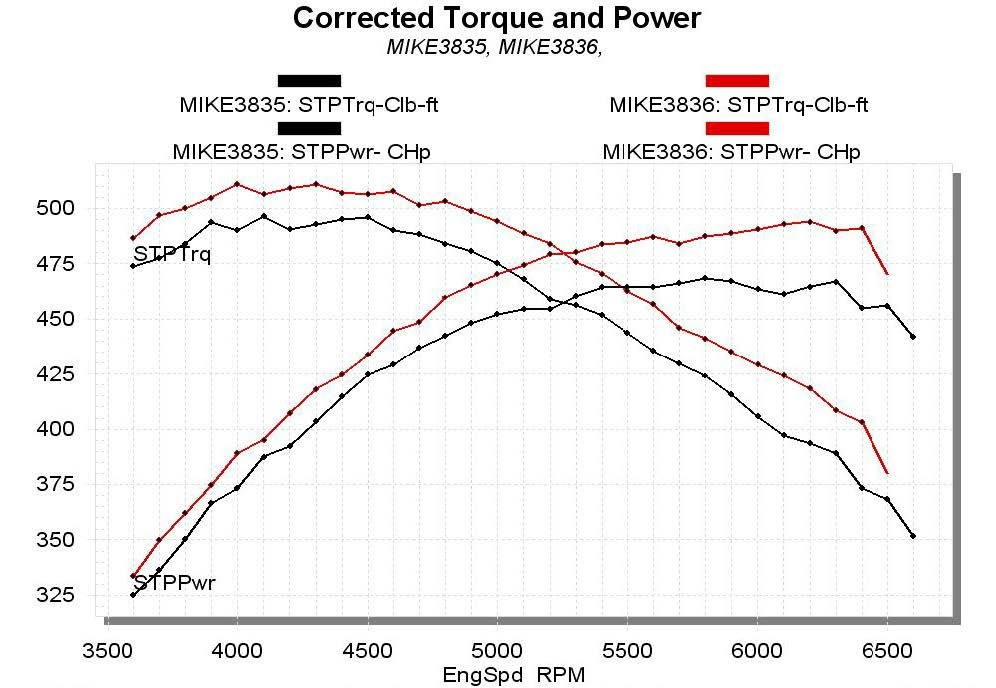

Below is a graph from a 493.9 HP alcohol circle track motor. As you can easily see there was a 25.6 HP and 14.63 lb.-ft. gain by just providing adequate air flow through the room.

These discoveries almost cost an engine builder his life with the excess alcohol and exhaust fumes when he entered the test cell after only 1 run. Not only can there be power left on the table it can be deadly.

Understandably test cells can cost money. There are also many ways to make you test cell useable and safe. Please consult with your SuperFlow salesperson for further information.